X

Product details

Product details

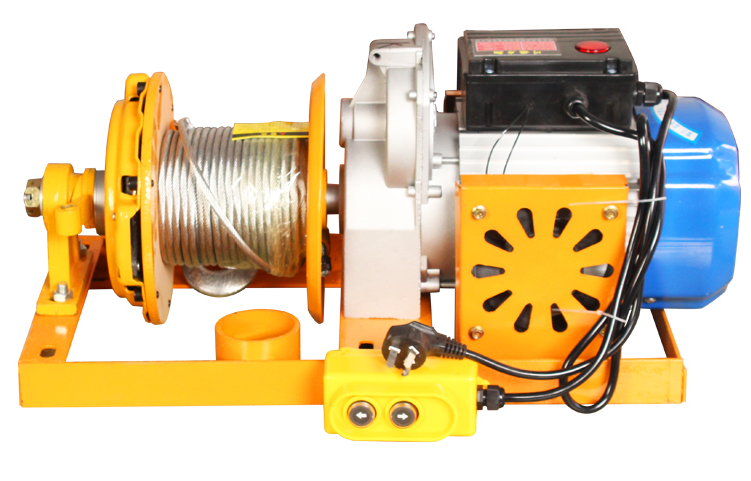

Product features:

Motor and gearbox shell including body are made of steel material heat dissipation fast, high hardness;

The shell material is strong and durable, and the control is simple. A variety of specifications, internal structure is complete. Small and stable, easy to use;

Large contact capacity, long service life. Hand support operation, light and convenient. Electric shock using standard contact, good conductivity;

Low noise, high power, with fast drop function, save time, improve work efficiency;

Automobile clutch pressure plate can realize the separation of drum and motor, can be quickly lowered, speed can be freely controlled;

Aluminum gearbox, fast heat dissipation, no oil leakage, precision gear, good bite.

Product use:

With crane, suitable for open air, rain, snow, dust erosion environment, mostly used for remote operation of cranes, electric hoists and other equipment.

Note:

1. Remove the end cover, insert the sealing sheath, and then fasten them on the end face of the button by screws;

2. Remove the bottom cover, insert all the control wires into the sealing sheath, and fasten them to the wiring ends of each button one by one according to the electrical schematic diagram;

3. Check or test whether the wiring is correct. If everything is normal, bind the lead and fix it, and then reinstall the bottom cover.

4. The brake is in a non-working state. The method of using the brake is to step on the brake with your foot and control the speed of lowering the brake.

5. Pull the lever in, separate the drum from the motor, and quickly lower it. Pull the lever outward, and the drum and motor rotate simultaneously.

Maintenance:

1. The electric hoist must keep enough lubricating oil in use, and keep the lubricating oil clean, should not contain impurities and dirt;

2. In use, the electric hoist must be checked regularly by specialized personnel, and measures should be taken in time when the fault is found, and carefully recorded;

3. In use, it is prohibited to use in an impermissible environment, and in excess of the rated load and rated closing times per hour (120 times).